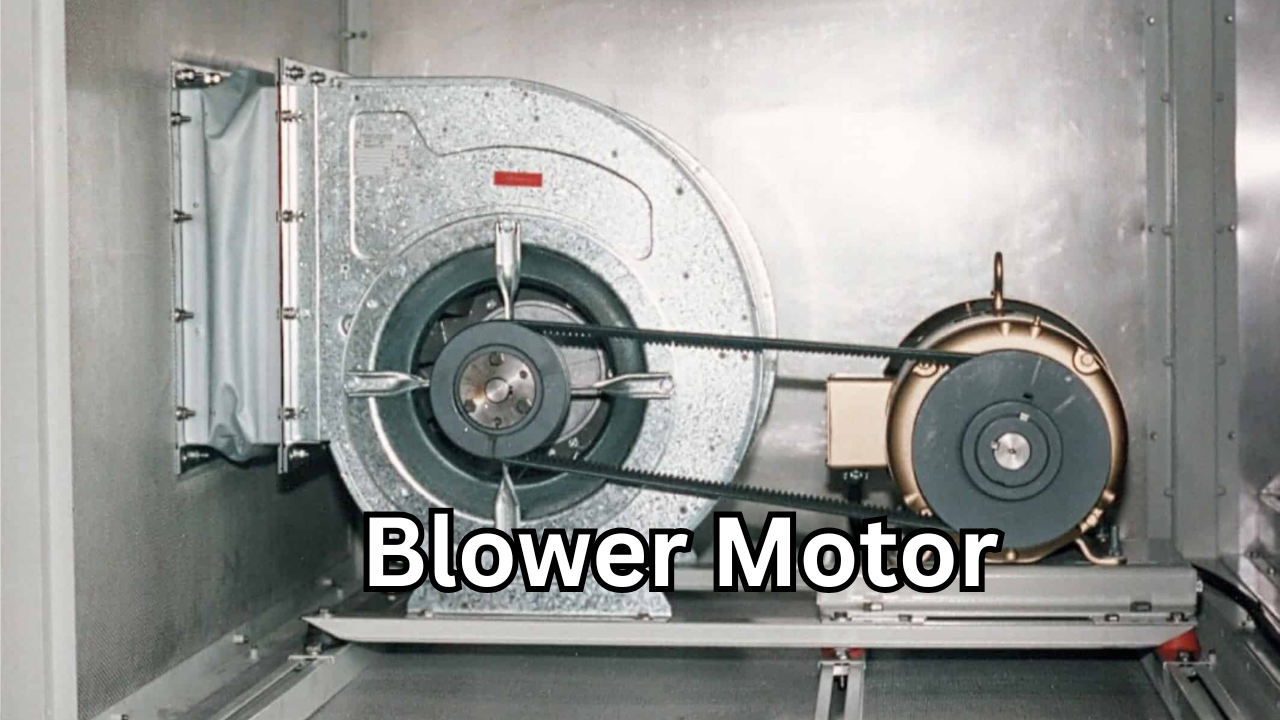

Blower Motor Reliability: A Powerful Guide to Lasting Performance

A blower motor plays a quiet yet critical role in keeping indoor environments comfortable, safe, and energy-efficient. Found at the heart of HVAC systems, this component circulates air through ductwork and maintains consistent temperature control throughout a building. When it performs well, comfort feels effortless; when it fails, the entire system can feel unreliable. This guide explores how it works, why it matters, common issues, maintenance best practices, and how to make informed decisions for long-term performance.

Understanding How Air Circulation Systems Work

Every modern heating and cooling setup depends on controlled airflow. The fan assembly inside an HVAC unit draws air across heating elements or cooling coils and pushes it through vents to living or working spaces. Without steady airflow, even the most advanced furnace or air conditioner cannot deliver results efficiently.

The electric motor at the center of this process converts electrical energy into mechanical motion, spinning the fan blades at varying speeds. Speed control allows systems to respond to changing temperature demands, maintain balanced pressure, and improve overall comfort. Because this component runs frequently, especially during peak seasons, durability and efficiency are essential.

Why This Component Matters More Than You Think

Airflow directly affects indoor air quality, system efficiency, and energy consumption. Weak or inconsistent circulation can lead to hot and cold spots, excess humidity, or dust buildup. Over time, inefficient airflow forces HVAC systems to work harder, increasing wear on parts and raising utility bills.

A blower motor that distributes air evenly supports filtration and lower operating costs. Both residential and commercial environments benefit from this reliability, which fosters healthier, more predictable indoor spaces.

Common Types Used in Modern HVAC Systems

Manufacturers design motors to meet different performance and efficiency goals. The most common categories include single-speed, multi-speed, and variable-speed designs. Single-speed options operate at one constant rate and are typically found in older or budget systems. Multi-speed versions adjust airflow in set increments, offering better control.

Variable-speed technology represents the most advanced option, automatically adjusting output to match real-time demand. These units run more quietly, consume less energy, and provide smoother temperature control. Although the upfront cost can be higher, long-term savings and comfort gains often justify the investment.

Blower Motor Performance and Efficiency Explained

When evaluating efficiency, it helps to understand how power usage and airflow relate. High-efficiency systems are designed to move the same volume of air using less electricity. Advanced electronics, improved bearings, and smart controls all contribute to reduced energy loss.

A blower motor operates best within its optimal load range, minimizing strain and maintaining airflow. Proper system design and installation are as crucial as choosing the right motor for efficiency and long life.

Signs of Wear or Potential Failure

Like any mechanical component, motors show warning signs before failing completely. Unusual noises, such as grinding or squealing, often indicate bearing wear or debris buildup. Reduced airflow, inconsistent temperatures, or frequent system cycling can also point to underlying problems.

Electrical symptoms deserve attention as well. Tripped breakers, burning smells, or delayed startup may signal overheating or wiring issues. Addressing these signs early can prevent costly breakdowns and protect other HVAC components from damage.

Maintenance Practices That Extend Service Life

Regular maintenance is one of the most effective ways to preserve performance. Simple steps, such as changing air filters on schedule, reduce resistance and prevent overheating. Keeping vents unobstructed allows air to move freely, reducing strain on internal components.

Professional inspections add another layer of protection. Technicians can check electrical connections, lubricate moving parts, and verify airflow settings. With consistent care, a quality blower motor can operate efficiently for many years beyond its average expectancy.

Energy Savings and Long-Term Cost Benefits

Efficiency improvements often translate directly into financial savings. Systems with modern motors typically consume less electricity, especially during partial-load operation. Over time, these savings can offset higher purchase prices and reduce the total cost of ownership.

Efficient airflow eases stress on other HVAC parts, limiting repairs and extending system life for greater reliability.

Choosing the Right Replacement Option

When replacement becomes necessary, compatibility and efficiency should guide the decision. Matching voltage, horsepower, and airflow requirements ensures safe operation. Consulting system specifications or a qualified technician helps avoid costly mismatches.

Upgrading to a newer blower motor design can significantly improve comfort and efficiency, even in older systems. Many homeowners and facility managers find that targeted upgrades provide noticeable improvements without requiring full system replacement.

Installation Quality and Professional Expertise

Even the best component can underperform if installed incorrectly. Proper alignment, secure mounting, and accurate wiring all affect reliability. Incorrect installation can lead to vibration, noise, or premature failure.

Working with experienced professionals ensures that the motor integrates seamlessly with existing controls and ductwork. This attention to detail protects warranties, maintains safety standards, and delivers expected performance gains.

Environmental Impact and Sustainability Considerations

Energy-efficient motors help reduce carbon emissions by lowering electricity demand. As building standards evolve, efficient airflow systems are playing an increasingly important role in sustainability strategies. Many modern designs meet or exceed regulatory efficiency benchmarks, supporting greener operations.

Selecting an efficient blower motor aligns comfort goals with environmental responsibility. Over its lifespan, reduced energy consumption can make a meaningful difference in overall resource use.

Final Thoughts on Reliability and Performance

A dependable airflow system is essential for comfort, efficiency, and indoor air quality. By understanding how motors work, recognizing early warning signs, and prioritizing maintenance, property owners can avoid disruptions and extend the life of their systems.

To sum up, reliable blower motor selection, professional installation, and consistent maintenance are key to delivering comfort, efficiency, and long-term savings. Focusing on these essentials ensures your HVAC system provides dependable performance and maximizes value over time.

Also Read: Dune Buggy: The Ultimate Thrill Ride for Adventure Lovers

1 comment